Advanced Materials and Chemicals

Lightweight Materials Market

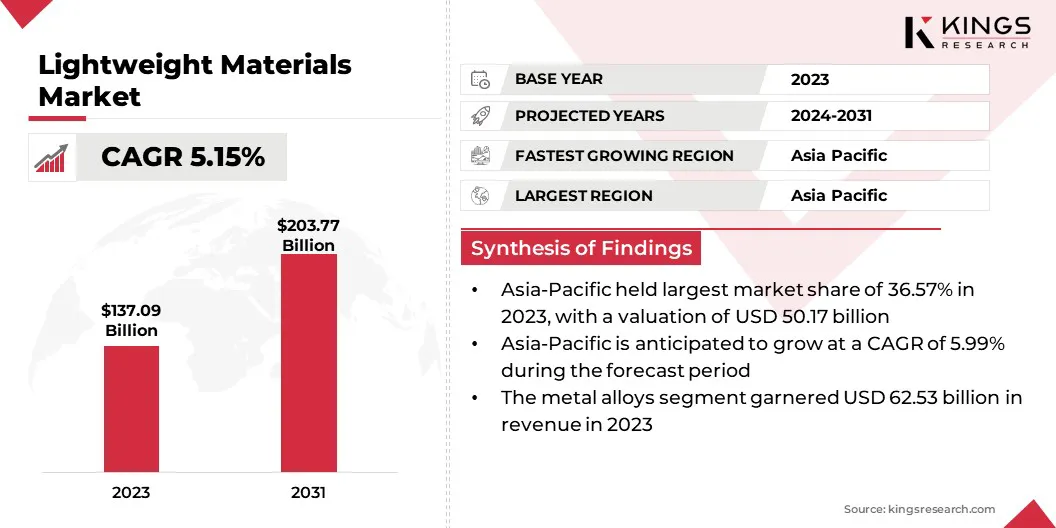

Lightweight Materials Market Size, Share, Growth & Industry Analysis, By Material Type (Metal Alloys, Composites, Plastics), By Application (Automotive, Aviation, Energy, Others), and Regional Analysis, 2024-2031

Pages : 120

Base Year : 2023

Release : January 2025

Report ID: KR1159

Lightweight Materials Market Size

The global Lightweight Materials Market size was valued at USD 137.09 billion in 2023 and is projected to grow from USD 143.40 billion in 2024 to USD 203.77 billion by 2031, exhibiting a CAGR of 5.15% during the forecast period.

The global market is experiencing steady growth due to the demand for lightweight materials in renewable energy applications, mainly wind and solar power. The rising demand for lightweight materials in construction and transportation sector is also driving market growth.

In the scope of work, the report includes service offered by companies such as Alcoa Corporation, ArcelorMittal, Bayer AG, Cytec Solvay Group, Evonik Industries, Exxon Mobil Corporation, Formosa Plastic Group, Allegheny Technologies Incorporated, Hexcel Corporation, PPG Industries Inc., and others.

The surge of metal alloys, specially aluminum, in the renewable energy sector is driving the growth of the lightweight materials market. Solar panels made from aluminum are lightweight and offer sturdiness, durability, good conductivity, and reflectivity.

Aluminum is also known for offering corrosion-resistance , mainly in hydropower infrastructure. The turbine blades made from aluminum are efficient, durable, and can resist water force.

- In November 2024, according to the ministry of new and renewable energy, India plans to generate 50% of its energy from clean and renewable sources by 2030. Additionally, it seeks to reach a non-fossil energy capacity of 500 gigawatts. India currently ranks fourth in installed onshore wind energy capacity.

Lightweight materials have a lower density and weight than traditional materials. They are designed to provide strength and utility while minimizing the total structural and product weight. The performance of lightweight materials depends on the mixture of alloys and composites utilized during the manufacturing.

Lightweight materials provide higher fuel efficiency, payload capacity, improved performance, and a lower environmental impact. These materials are highly durable and resistant to wear and tear, and therefore, find applications in construction.

Manufacturers are focusing on manufacturing lightweight materials owing to the rising sales of electric vehicles and the increasing fuel prices. Lightweight materials, such as advanced composites, aluminum, carbon fiber, and high-strength polymers, are being used to reduce total weight while maintaining and improving structural integrity. This automotive trendis being driven by regulations to lower greenhouse gas emissions and boost fuel efficiency.

- In May 2023, Cabot Corporation launched the latest ENTERA aerogel particles. These aerogel particles act as a thermal insulation additives, allowing the construction of ultra-thin thermal barriers for lithium-ion batteries in EVs.

Aerospace manufacturers use these materials to improve aircraft performance and fuel efficiency, which saves cost and lowers the carbon footprint. The building sector uses lightweight materials as they offer structural support without additional foundations and at a lower transportation expense. Advances in material sciences, low-cost production, and rising demand for EVs drive the market growth.

Lightweight Materials Market Growth Factors

Increasing demand for electrical vehicles (EVs) is driving the growth of the lightweight materials market. EVs require effective energy utilization to maximize battery life and range, therefore, reducing a vehicle’s weight becomes essential.

To achieve this, lightweight materials, such as carbon fiber-reinforced plastics, aluminum, and high-strength steel, are used in EV production. With increasing consumer preference for EVs due to their environmental benefits and lower operational costs, manufacturers are investing in lightweight technology to boost performance and extend driving range.

Lightweight materials enhance vehicle dynamics, acceleration, and handling while maintaining structural strength in case of an accident. The lightweight material market faces challenges related to a lack of skilled professionals, for implementing innovative processes for manufacturing, maintaining quality standards, and maximizing the use of lightweight metals in product design.

Many companies lack specific knowledge of lightweight metal manufacturing, innovative joining techniques, and surface treatment processes. Addressing these challenges needs efforts from industry stakeholders, government organizations, and educational institutions.

Seminars, awareness campaigns, workshops, and training programs can help educate manufacturers, designers, and end-users, about the advantages and best practices regarding lightweight material. Partnerships between industries and academic institutes can promote research collaborations and skill development, which focuses on lightweight material manufacturing.

Lightweight Materials Industry Trends

The increasing focus on fuel efficiency and reducing greenhouse gas emissions has driven automotive manufacturers toward lightweight vehicles. These use advanced components, such as high-strength steel, carbon fiber composites, and aluminum alloys, to reduce vehicle weight and maintain structural integrity and safety. As they use less energy to run, lightweight vehicles offer better fuel economy and release fewer greenhouse gases.

- In May 2024, according to United Nations, the transport sector accounted for 30% of CO2 emissions in developed nations and around 23% of total man-made CO2 emissions on a global scale.

This shift is consistent with strict environmental regulations and consumer demand for eco-friendly modes of transportation. As a result, lightweight materials have become a significant option to balance performance and efficiency with sustainability.

The increasing environmental awareness is also driving market growth. With growing concerns about climate change and carbon emissions, industries are facing a pressure to adopt more eco-friendly methods. Lightweight materials reduce energy consumption and greenhouse gas emissions throughout the product lifecycle.

Therefore, incorporating lightweight materials in automobiles, aerospace components, or building materials, contributes to achieving environmental goals by increasing fuel economy, lowering transportation emissions, and decreasing construction waste. Consumer preferences are gradually shifting toward eco-friendly products, encouraging manufacturers to integrate lightweight materials into their designs.

Such items offer environmental benefits that appeal to consumers who acknowledge sustainability and base their purchasing decisions on sustainable value. Thus, rising environmental awareness is expected to drive growth of the lightweight materials market.

Segmentation Analysis

The global market has been segmented based on material type, application, and geography.

By Material Type

Based on material type, the market has been categorized into metal alloys, composites, and plastics. The metal alloys segment garnered the highest revenue of USD 62.53 billion in 2023.

Metal alloys such as aluminum are used in automotive and aerospace applications owing to its strength and age-hardening tendency. In most cases, high strength steel is used instead of conventional steel. It is extensively used in the automotive industry where it to decrease vehicle weight by 25%. Steel demand is rising mainly because of its recyclable nature.

Magnesium is mostly used in automobiles and electronics, whereas titanium is commonly used in a variety of applications due to its high availability and ease of usage. Despite its high cost, titanium is use for increasing strength and durability in specialty applications.

By Application

Based on application, the lightweight materials market has been divided into automotive, aviation, energy, and others. The automotive segment captured the largest market share of 41.35% in 2023. The increasing standard of living, industrialization, increasing adoption of electric vehicles, and new product launches are driving the market growth.

The growth is also driven by technological advancements, automation, and the expansion of manufacturing sectors that promote economic development and job creation. The growing use of electric vehicles (EVs) has significantly shifted consumer and industrial preferences.

With environmental concerns and regulations promoting net-zero carbon emissions, EVs have gained popularity because of their environmental friendliness, lower operating costs, and advancements in battery technology that make them more affordable and practical.

Lightweight Materials Market Regional Analysis

Based on region, the global market has been classified into North America, Europe, Asia-Pacific, MEA, and Latin America.

Asia-Pacific lightweight materials market accounted for the largest revenue share of 36.57% in 2023, with a valuation of USD 50.13 billion. China, a key electronics automotive hub in the Asia-Pacific, has adopted materials such as aluminum and sophisticated composites, especially in the electric vehicle (EV) sector, where lightweight materials improve performance and range.

Leading companies, including NIO and BYD, are at the forefront of incorporating these materials into vehicle designs. Furthermore, the aerospace industry has contributed to the increasing demand for lightweight materials.

The demand for lightweight materials such as aluminum, plastics, and advanced composites, is fostering investment in the national automobile, aircraft, and infrastructure sectors. These materials enhance energy efficiency, performance, and regulatory compliance.

Furthermore, many local enterprises are adopting new materials and production methods as a result of government initiatives and subsidies that foster industrial innovation.

Europe lightweight materials market is anticipated to witness significant growth, registering a CAGR of 5.55% over the forecast period. This growth is mainly proeplled by its strong emphasis on sustainability, energy efficiency, and technological innovation.

The automobile and aerospace sectors have contributed significantly to this growth, with European manufacturers employing new lightweight materials to meet rigorous pollution rules and enhance fuel efficiency. The region's commitment to minimizing carbon emissions has resulted in the widespread use of carbon fiber, aluminum alloys, and high-strength plastics.

Germany, France, and Italy are at the forefront of manufacturing and R&D, focusing on incorporating these materials into traditional and electric car designs, as well as aircraft production.

Competitive Landscape

The global lightweight materials market report will provide valuable insight with an emphasis on the fragmented nature of the industry. Prominent players are focusing on several key business strategies such as partnerships, mergers and acquisitions, product innovations, and joint ventures to expand their product portfolio and increase their market shares across different regions.

Companies are implementing impactful strategic initiatives, such as expanding services, investing in research and development (R&D), establishing new service delivery centers, and optimizing their service delivery processes, which are likely to create new opportunities for market growth.

List of Key Companies in Lightweight Materials Market

- Alcoa Corporation

- ArcelorMittal

- Bayer AG

- Cytec Solvay Group

- Evonik Industries

- Exxon Mobil Corporation

- Formosa Plastic Group

- Allegheny Technologies Incorporated

- Hexcel Corporation

- PPG Industries Inc.

Key Industry Developments

- June 2024 (Launch): Toray Industries launched Toraysee cleaning cloths, made from their patented polyester derived from recycled plastic bottles and other materials. The cloths features microfibers with a diameter of just two microns, delivering cleaning performance comparable to typical fibers.

- August 2024 (Acquisition): Alcoa Corporation completed its acquisition of Alumina Limited, gaining full ownership of the Alcoa World Alumina and Chemicals (AWAC) joint venture. Previously holding a 60% stake, Alcoa now fully owns AWAC, which operates several bauxite mines and alumina refineries in key regions, including Brazil, Guinea, and Australia.

The global lightweight materials market has been segmented as:

By Material Type

- Metal Alloys

- Composites

- Plastics

By Application

- Automotive

- Aviation

- Energy

- Others

By Region

- North America

- U.S.

- Canada

- Mexico

- Europe

- France

- UK

- Spain

- Germany

- Italy

- Russia

- Rest of Europe

- Asia-Pacific

- China

- Japan

- India

- South Korea

- Rest of Asia-Pacific

- Middle East & Africa

- GCC

- North Africa

- South Africa

- Rest of Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

CHOOSE LICENCE TYPE

CUSTOMIZATION OFFERED

Additional Company Profiles

Additional Countries

Cross Segment Analysis

Regional Market Dynamics

Country-Level Trend Analysis

Competitive Landscape Customization

Extended Forecast Years

Historical Data Up to 5 Years